Top 13 Use Cases Applications of AI in Manufacturing in 2023

Joel has over 18 years of diverse global experience and multiple leadership assignments across Big 4 consulting, IT services and product engineering. He has distinguished himself by providing strategic vision and leadership for solving common industry problems on cutting-edge technologies. She has successfully expanded service portfolios globally, including major roles at Microsoft, NTT Data, Tech Mahindra. Proficient in diverse database technologies and Cloud platforms (AWS, Azure), she excels in operational excellence. Beyond her professional achievements, Sridevi also serves as a Health & Wellness coach, impacting IT professionals positively through engaging sessions. Performance optimization is a critical aspect of manufacturing, and artificial intelligence is proving to be a game changer in this regard.

Some manufacturing robots are equipped with machine vision that helps the robot achieve precise mobility in complex and random environments. The lack of universal industrial data has been another major obstacle slowing the adoption of AI among mainstream manufacturers. Manufacturing data is often localized or specific to a particular industry domain or a company’s operations. AI systems that use machine learning algorithms can detect buying patterns in human behavior and give insight to manufacturers.

The Future of Industrial AI in Manufacturing

The software examines manufacturing components with industrial radiography (X-ray) and images to determine the integrity of each part and its internal structure. With only a specialized technician, the examination process can be highly manual and error-prone. Amid the rapid evolution of modern manufacturing, the infusion of artificial intelligence (AI) has ignited an unparalleled revolution. This article covers the impact of AI in manufacturing, spotlighting its exceptional use cases. From predictive maintenance thwarting costly breakdowns to personalized manufacturing tailored to individual needs, AI’s influence permeates production processes.

There are many things that go above and beyond just coming up with a fancy machine learning model and figuring out how to use it. This capability can make everyone in the organization smarter, not just the operations person. For example, machine learning can automate spreadsheet processes, visualizing the data on an analytics screen where it’s refreshed daily, and you can look at it any time. AI is widely used in smart manufacturing for automation, order management, and scheduling, where robotic integration is key.

How Artificial Intelligence Is Used in Manufacturing

By detecting this early on, manufacturers can take preventative action and avoid costly downtime. Only a few companies have used AI in products and services, but investment in AI is growing rapidly. Particularly, in shortening design time, enhancing customer experience, and improving marketing efficiency. Manufacturers face challenges in improving product performance, reducing energy consumption, and accelerating design cycles. AI applications like generative design help expedite the design process by exploring multiple solutions. AI also holds potential in enhancing customer experience, providing customer insights, and increasing marketing efficiency.

Predictive maintenance is like predicting when things machines might break down. Instead of waiting for a problem, it checks the health of equipment and machinery and predicts their life. Cobots learn different tasks, unlike autonomous robots that are programmed to perform a specific task. They’re also skilled at identifying and moving around obstacles, which lets them work side by side and cooperatively with humans.

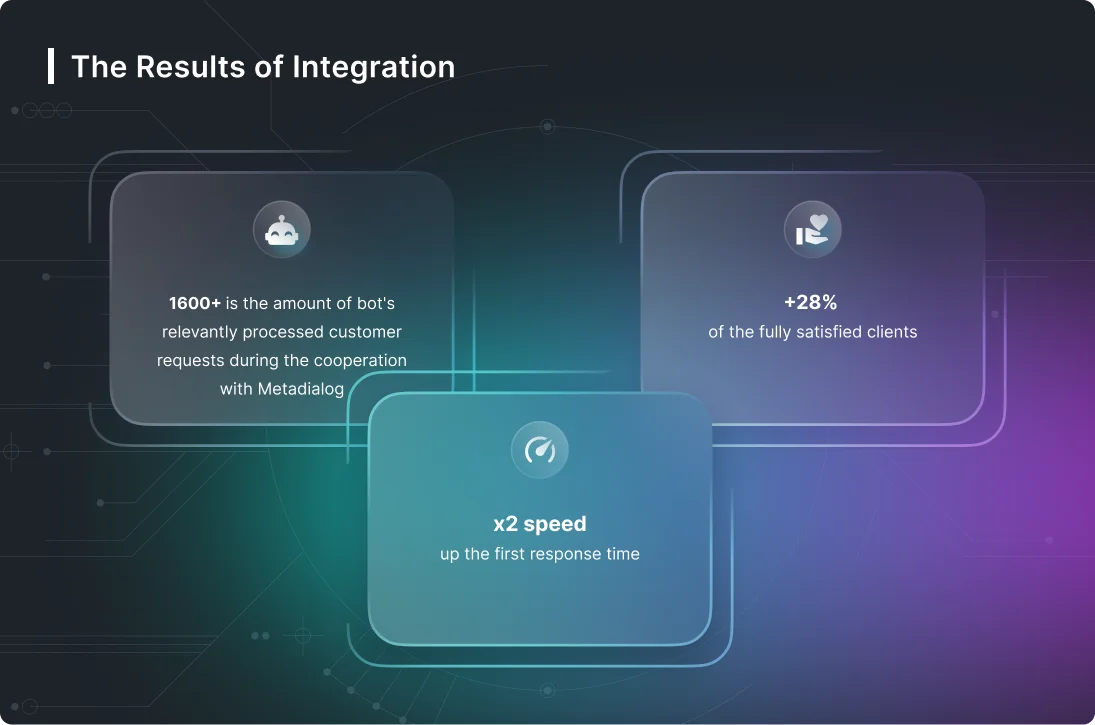

Read more about https://www.metadialog.com/ here.

Leave a Reply